How Is Perforated Metal Fabricated?

February 21st, 2023

Perforated metal is a versatile material that has become increasingly popular in a variety of industries, including construction, architecture, and interior design. It is a type of metal sheet that has been punched with a series of holes, which can serve a variety of functions, including providing ventilation, sound insulation, or simply adding an aesthetic design element to a structure.

Perforated metal manufacturers play a crucial role in the production of this material, ensuring that it is of high quality, durable, and meets the needs of the end-users. In this blog, we’ll explore the world of perforated metal manufacturers, their processes, and the benefits of working with them.

Perforated Metal Manufacturing Process

The process of manufacturing perforated metal sheets typically involves the following steps:

Material selection: Perforated metal can be made from a variety of materials, including steel, aluminum, brass, copper, and stainless steel. The material selection will depend on the intended use of the perforated metal and the desired properties such as durability, weight, and appearance.

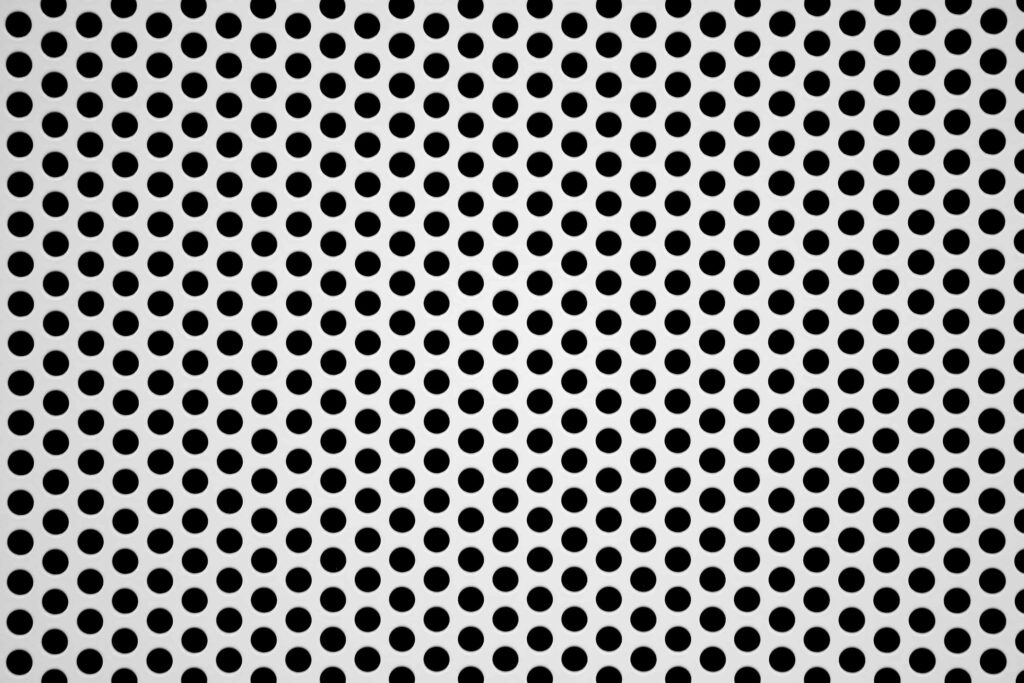

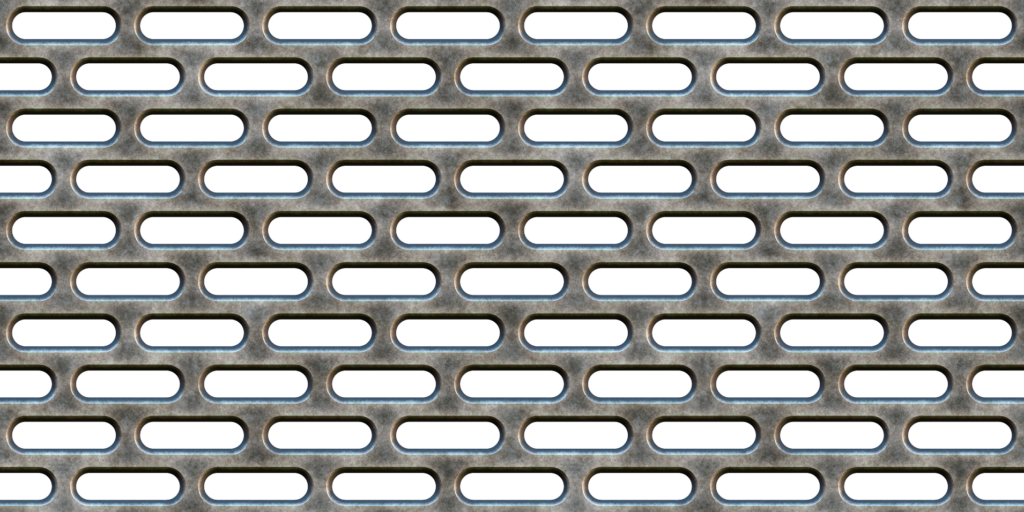

Hole punching: The perforation process involves punching a series of holes in the metal sheet. The size, shape, and pattern of the holes can be customized according to the needs of the customer. The punching can be done manually or by using a perforation machine.

Surface finishing: After the perforation process is complete, the metal sheet is usually coated or finished to improve its appearance and durability. The coating or finish can include painting, powder coating, anodizing, or plating.

Quality control: Perforated metal manufacturers ensure that the quality of the product is consistent and meets the required specifications. They use various testing methods to check the quality of the metal sheets, such as visual inspection, thickness testing, and surface roughness testing.

Benefits of Working with Perforated Metal Manufacturers

Customization: Perforated metal manufacturers can produce sheets that are customized to the needs of the customer. They can create sheets with specific hole sizes, patterns, and shapes, as well as sheets that are made from different materials. This level of customization allows the end-user to achieve their desired results while meeting their specific needs.

Expertise: Perforated metal manufacturers have the expertise and knowledge to produce high-quality products that meet industry standards. They use specialized equipment and processes to ensure that the perforated metal sheets are of consistent quality and meet the specifications of the end user.

Cost-effective: Working with perforated metal manufacturers can be cost-effective for the end user. Manufacturers often offer bulk discounts and can help customers choose the most appropriate material and perforation method for their specific needs.

Time-saving: Perforated metal manufacturers can produce sheets of metal more quickly than if the end-user attempted to do it themselves. This saves time and resources, allowing the end-user to focus on other important aspects of their project.

Applications of Perforated Metal Sheets

Perforated metal sheets have a wide range of applications in various industries, including construction, architecture, and interior design. Some of the most common applications of perforated metal sheets include:

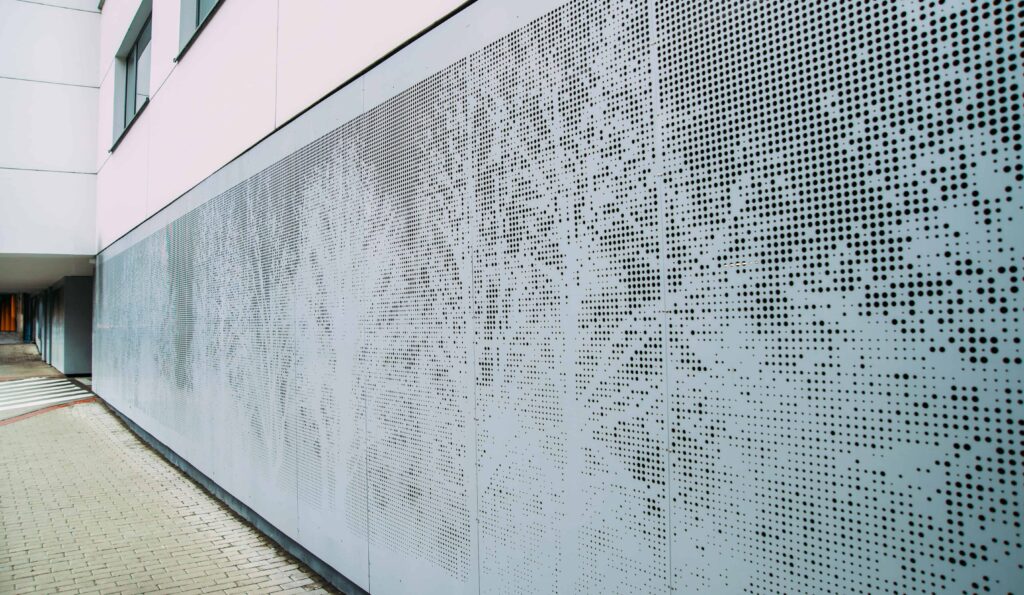

Building facades: Perforated metal sheets can be used as building facades to create an interesting and eye-catching exterior. They can be used to create patterns, designs, and shapes that can add interest and appeal to a building’s exterior.

Sound insulation: Perforated metal sheets can be used as a sound insulation material in educational facilities, recording studios, and other settings where sound insulation is important.

Ventilation: Perforated metal sheets can be used as ventilation covers in HVAC systems and other applications where ventilation is needed.

Interior design: Perforated metal sheets can be used in interior design applications, such as decorative panels, partitions

Peterson Company is a fiberglass grating and perforated metal fabricator since 1931. The full-service facility is located in Salt Lake City and specializes in manufacturing specialty metal products for light commercial and heavy industrial projects.