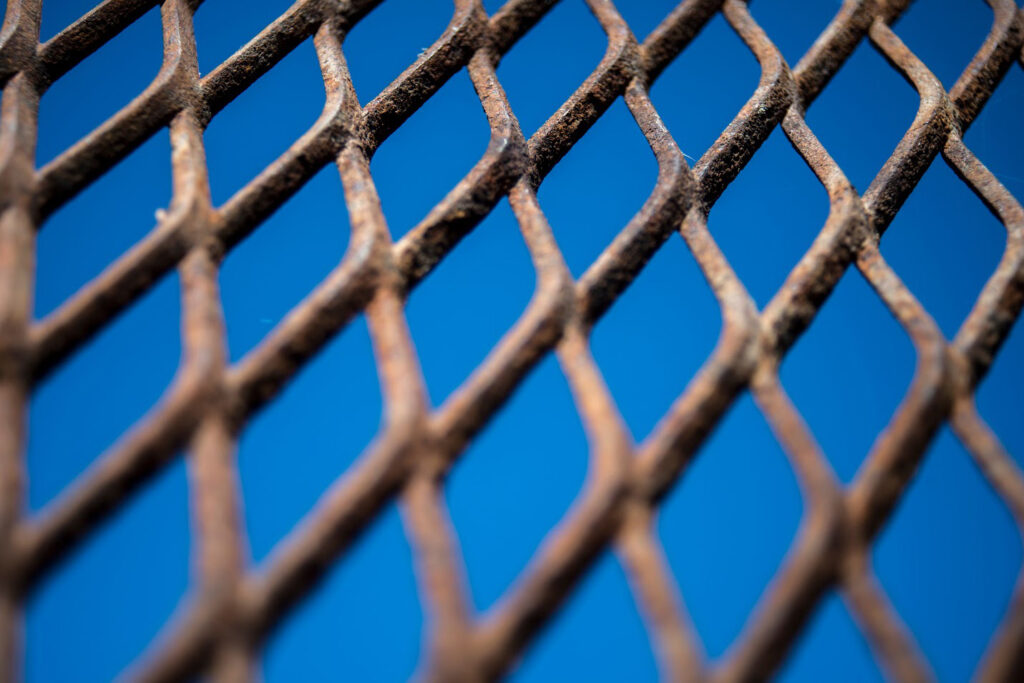

How is Expanded Metal Used in Fencing & Grating?

February 22nd, 2023

Expanded metal is a type of metal sheet that is made by cutting and stretching metal sheets into diamond-shaped patterns. It is a versatile and cost-effective material that is used in a variety of applications, such as fencing, grating, security screens, decorative elements, and more. The expanded metal industry has grown significantly over the years, with many manufacturers specializing in the production of this material.

Expanded metal manufacturers use a variety of different metals to make their products, including aluminum, brass, copper, stainless steel, and carbon steel. The type of metal used depends on the intended application of the expanded metal. For example, aluminum expanded metal is lightweight, corrosion-resistant, and often used in architectural applications, while stainless steel expanded metal is stronger, more durable, and used in industrial and heavy-duty applications.

Another challenge for expanded metal manufacturers is the environmental impact of their production processes. Many of the metals used in expanded metal production are non-renewable resources, and the manufacturing process can also generate waste and emissions. To address these concerns, many manufacturers have implemented sustainability initiatives such as using recycled materials, reducing waste, and using renewable energy sources.

In conclusion, expanded metal manufacturers play an important role in providing a versatile and cost-effective material for a range of applications. With the ability to provide strength and durability while also allowing for airflow and light penetration, expanded metal is a popular choice for applications in construction, architecture

Peterson Company carries expanded metal in a variety of applications, such as stainless steel, carbon steel, aluminum, and titanium, among many others. A full list of all the expanded metal options is available online.