Grip Strut

Products > Plank Grating > Grip Strut

Grip Strut

The open design of GRIP STRUT® minimizes maintenance, permitting quick drainage of fluids, chips, grease and mud, and ice accumulation shears easily under normal foot pressure.

At Peterson Company we have our own fabricating shop, which gives us the capability to cut to specification.

Another common use in our area is at the ski resorts. The snow falls through the planks providing easy maintenance.

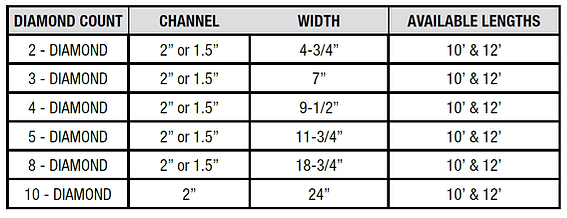

AVAILABLE IN STEEL AND ALUMINUM

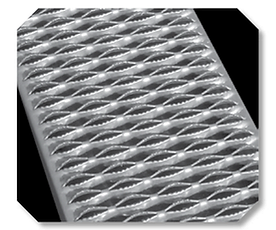

SERRATED GRIP STRUT GRATING- Standard Serrated Surface offers excellent slip resistance wherever maximum safety underfoot is essential. Material meets anti-slip values set forth in Federal Specification RR-G-1602A.

NON-SERRATED GRIP STRUT GRATING- For all-purpose use where a high degree of slip resistance is required plus a smoother texture and design. Product is non-stock and subject to extended lead time.

STANDARD GRIP STRUT GRATING- Available in materials and sizes to meet most load/span requirements. May be used as is or cut, welded, or punched to suit requirements.

MAINTENANCE-FREE DESIGN- Permits quick drainage of fluids, chips, grease and mud. Any ice accumulation shears easily under normal foot pressure. Open design allows convenient access for cleaning. It is easily cleaned with brush, liquid or air spray to minimize overall maintenance.

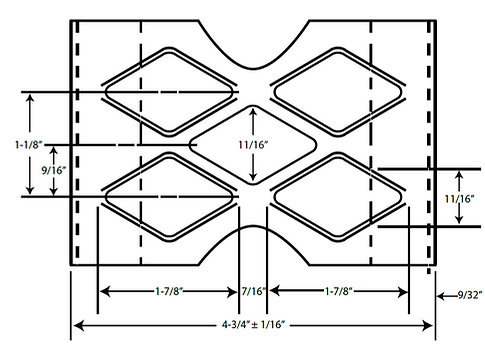

LONG LIFE- High strength-to-weight performance is achieved through depth of section and structural design. Bridged struts with integral side channels form a plank that can support loads with minimum transverse and longitudinal deflection. This sturdy construction provides the advantages of heavy load-carrying capacity with minimal deflection; rugged durability with longer-lasting performance.

EASY INSTALLATION- Light, easy-to-handle planks make installation simple and quick. They can be handled by one person. Most sections are rapidly bolted, clamped or welded into place, easily field-cut at virtually any angle, or fabricated to adapt to field conditions. Several attachments devices permit fastening to most existing surfaces allowing for fast installation or disassembly.

Grip Strut

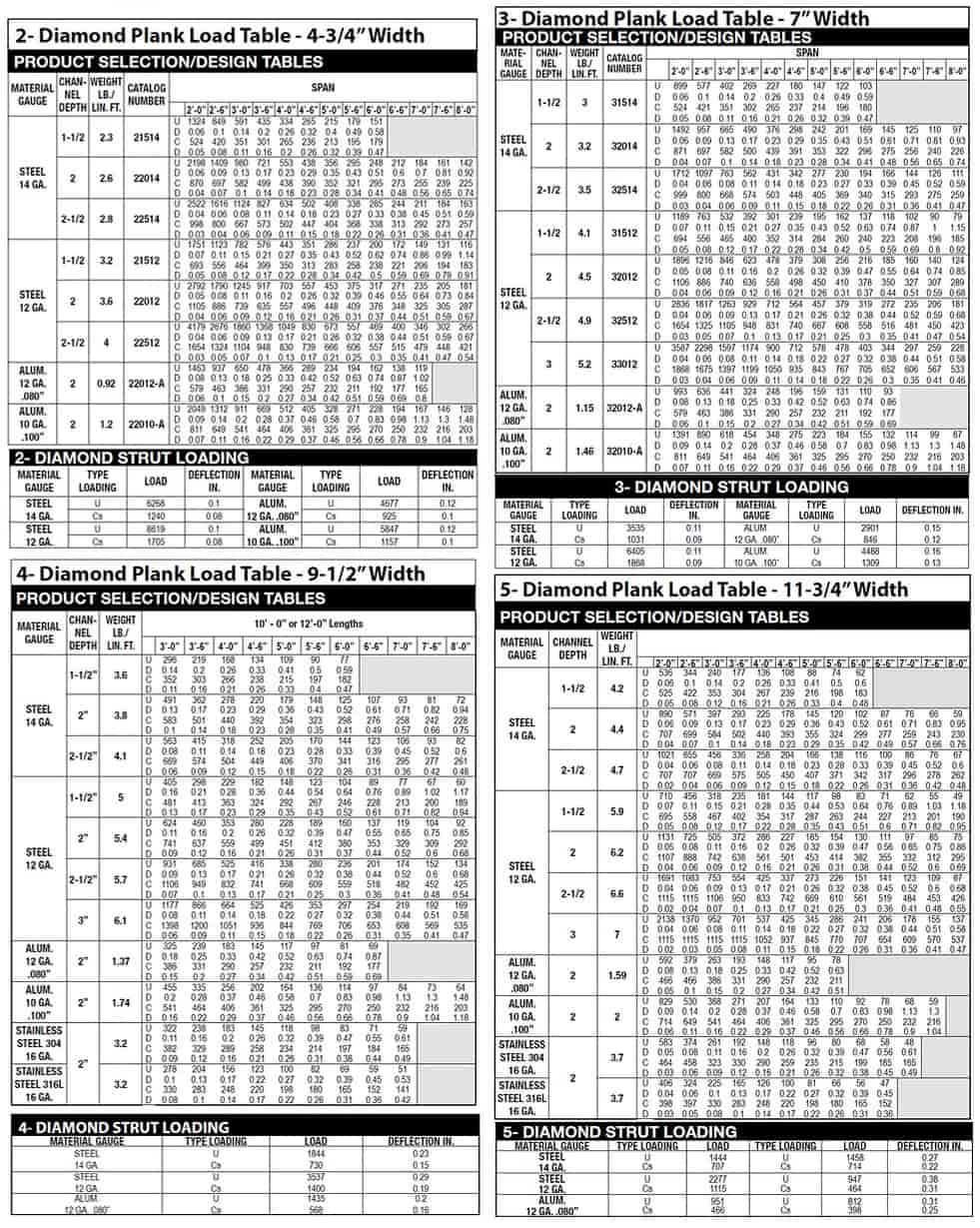

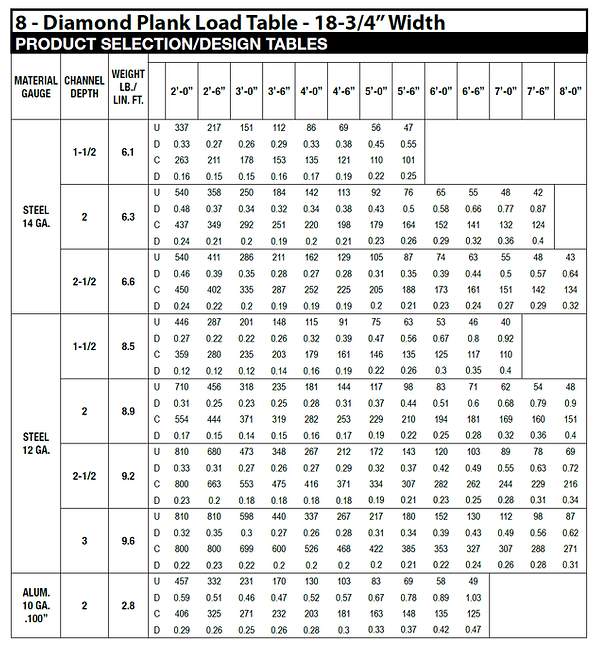

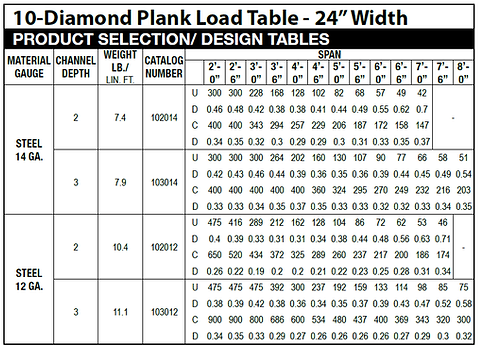

8 and 10-Diamond products are wide enough to require a change in the assumption used to prepare the 2-through 5-Diamond Product Selection/Design Tables. No longer will it be assumed that both side channels are equally effective in supporting a concentrated load. In fact, to provide a high level of safety, one side channel will be required to carry 100% of a concentrated load.

8 and 10-Diamond products are wide enough to require a change in the assumption used to prepare the 2-through 5-Diamond Product Selection/Design Tables. No longer will it be assumed that both side channels are equally effective in supporting a concentrated load. In fact, to provide a high level of safety, one side channel will be required to carry 100% of a concentrated load.

Diamond Anchors are shaped to fit in the diamond opening. Punched to receive 5/16″ carriage head bolt with square shank.