Why Steel is the Best for Cable Railing

November 8th, 2023Handrails, especially those for cable railing, can be constructed from various materials as long as they meet building code requirements and are strong and stable. However, of all the materials available, carbon steel or stainless steel—is the most recommended because it is corrosion-resistant, durable, and easy to maintain.

Before delving into the various materials, it’s crucial to grasp the fundamentals of cable handrails. This understanding will equip you with the knowledge to make informed decisions about your railing system.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cable Railing Building Code

To maintain safety for decks, landings, and stairways, handrails must comply with strict building codes established by the International Code Council (ICC) and local regulations. In Utah, the code states that the top rail must rest at a height between 34 and 38 vertical inches. However, the top rail can be higher in other states, so long as it is not taller than 42″ as specified by the ICC and follows local guidelines.

Construction

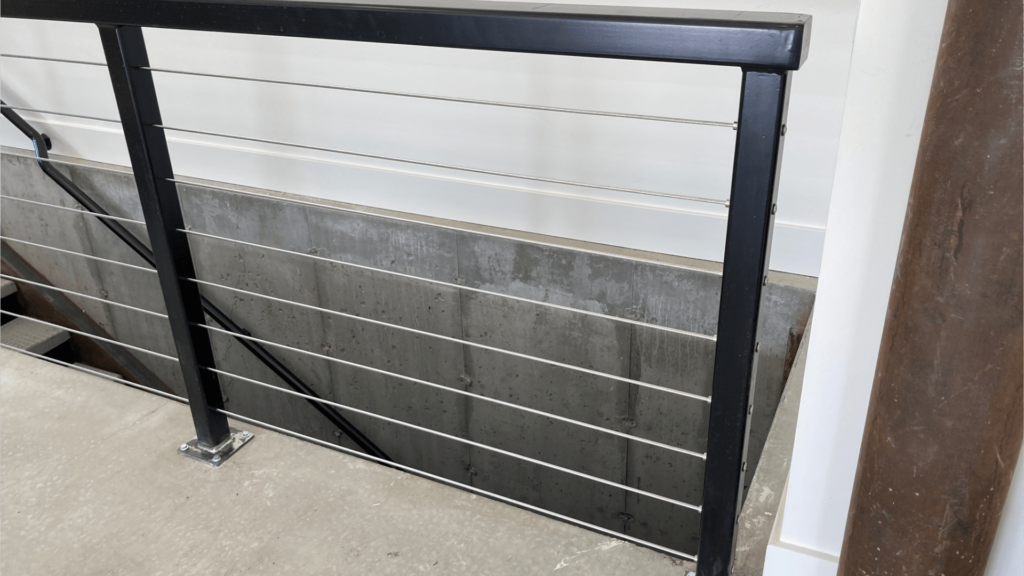

For cable railing, also known as a cable handrail system, the main components that make up the system are the frame and the cable infill. The frame consists of the top rail, which people grip or hold onto for support, and the posts, which both hold up the top rail and act as a frame for cable infill. Any rail system’s infill is the space between the top rail, posts, and the deck or landing. In some railing systems, this can be filled with glass or other materials or left open. Still, in a cable railing system, the infill consists of long, continuous horizontal steel cables that run through holes in the post from one end post to the other.

The infill for the cable railing should be made of rigid metal cables that don’t stretch. For this reason, we recommend using 1×19 construction, type 316 stainless steel strand, because others are less rigid and more likely to give or sag.

Materials for Cable Railings

The infill for cable railing should be made of rigid metal cables that don’t stretch. For this reason, we recommend using 1×19 construction, type 316 stainless steel strand, because others are less rigid and more likely to give or sag.

Coated cables from Ultra-tec are available for those looking for that extra spark of color in their design.

The frame, a crucial component of the railing system, should be robust and capable of bearing the weight of people leaning on it and elemental forces if installed outdoors. Frames are typically constructed from steel, wood, aluminum, and composite. However, many of these materials are susceptible to rot, crack, or rust over time. They may demand a significant amount of maintenance to maintain a sturdy railing that is both strong and visually appealing. On the other hand, steel stands out with its unparalleled strength and durability, which offer safety and security.

Pros of Using Steel

Steel, especially stainless steel, surpasses aluminum in terms of durability and corrosion resistance. It is less likely to dent or bend under the tension required in cable railing. This robustness and low maintenance requirements make stainless steel rails and posts a reassuring choice, whether installed indoors or outdoors.

Cons of Using Steel

Some prefer the look of wood or composite to steel, and they are perfectly entitled to that opinion. Also, steel frames are generally more expensive than other materials because they are more difficult to create.

Choose Steel Cable Railings

Steel’s strength, versatility, and durability are worth the extra cost for the peace of mind of knowing the railing will be strong for years to come. It is also a beautiful material that can add to any space while maintaining the safety of those who use it.

Contact Peterson Company to connect with someone who can help you with your next railing project.

—

Precision. Strength. Reliability. Get Top-Quality Steel Products With Peterson Company—Built to Last Since 1931. – Get A Quote Today!