How is Expanded Metal Used in Fencing & Grating?

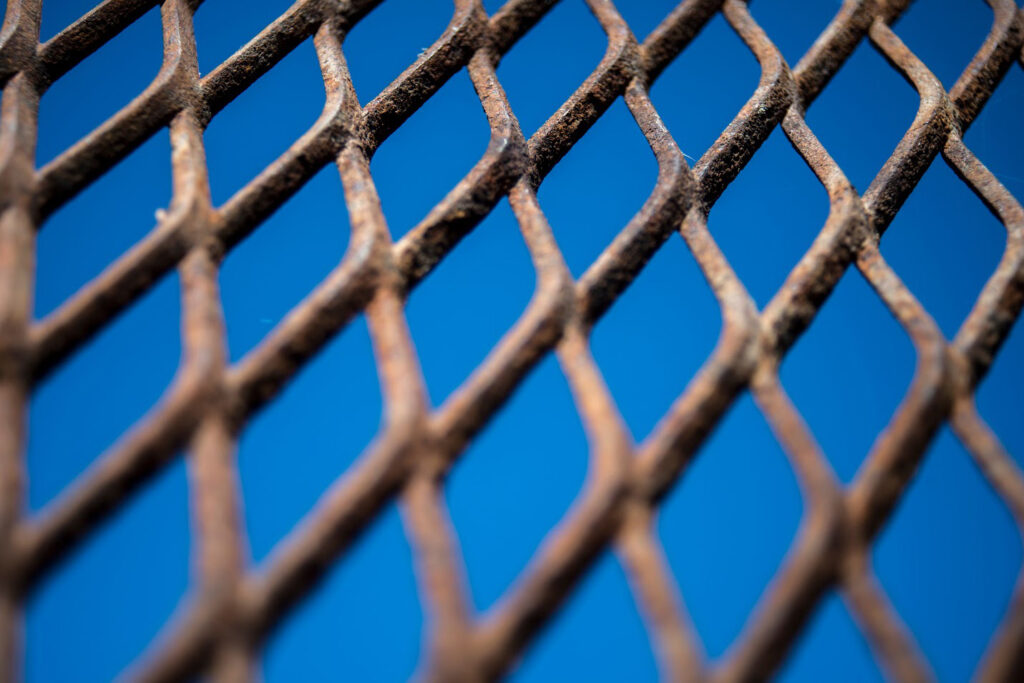

November 22nd, 2022Expanded metal is a type of metal sheet made by cutting and stretching metal sheets into diamond-shaped patterns. It is a versatile and cost-effective material used in a variety of applications, such as fencing, grating, security screens, decorative elements, and more. The expanded metal industry has grown significantly, with many manufacturers specializing in producing this material.

Expanded metal manufacturers, like Peterson Company is Salt Lake City and Denver, use various metals to make their products, including aluminum, brass, copper, stainless steel, and carbon steel. The type of metal used depends on the intended application of the expanded metal. For example, aluminum expanded metal is lightweight, corrosion-resistant, and often used in architectural applications, while stainless steel expanded metal is stronger, more durable, and used in industrial and heavy-duty applications.

EXTANDED METAL ADVANTAGES

One of the key advantages of expanded metal is its ability to provide strength and durability while allowing for airflow and light penetration. This makes it an ideal material for various architectural and industrial applications. For example, in construction, expanded metal can be used to create facades and sunshades, as well as for walkways, bridges, and railings. In industrial settings, expanded metal can be used for catwalks, stair treads, machine guards, and more.

Expanded metal manufacturers typically offer a range of different products, including standard and flattened expanded metal, micro mesh, and decorative patterns. Standard expanded metal is created by slitting and stretching metal sheets, while flattened expanded metal is created by passing the standard expanded metal through a flattening machine.

Micro mesh is a smaller, more finely detailed version of expanded metal often used for filtration applications. Decorative patterns can be created by cutting the expanded metal into custom shapes or using special dies to create intricate designs.

factors to consider to selecting a manufacturer

When choosing an expanded metal manufacturer, consider factors such as product quality, pricing, lead times, and customer service. It is also important to work with a manufacturer with experience in the specific application for which the expanded metal will be used. For example, an industrial application may require a stronger and more durable expanded metal than a decorative application.

Many expanded metal manufacturers also offer value-added services such as fabrication, finishing, and custom cutting. Fabrication services can include welding, shearing, and forming, while finishing services can include powder coating, anodizing, and painting. Custom cutting allows the expanded metal to be cut into specific shapes and sizes to fit the application’s needs.

the challenge of customization in expanded metal

One of the challenges for expanded metal manufacturers is balancing the need for customization with the need for efficiency and cost-effectiveness. Customization can be a time-consuming process that requires specialized equipment and expertise, but it is often necessary to meet the customer’s specific needs. However, manufacturers must also be able to produce their products efficiently and at a competitive price to remain competitive in the market.

Many expanded metal manufacturers have invested in technology and equipment to address this challenge for greater customization while improving efficiency. For example, computer numerical control (CNC) machines can create intricate shapes and patterns in the expanded metal, while automation can speed up the production process and reduce labor costs.

choose peterson company

Another challenge for expanded metal manufacturers is the environmental impact of their production processes. Many of the metals used in expanded metal production are non-renewable resources, and the manufacturing process can also generate waste and emissions. To address these concerns, many manufacturers have implemented sustainability initiatives such as using recycled materials, reducing waste, and using renewable energy sources.

In conclusion, expanded metal manufacturers are important in providing a versatile and cost-effective material for various applications. With the ability to provide strength and durability while also allowing for airflow and light penetration, expanded metal is a popular choice for applications in construction, architecture

Peterson Company, located in Utah and Denver, carries expanded metal for a variety of applications, including stainless steel, carbon steel, aluminum, and titanium. A full list of all the expanded metal options is available online.

—

Precision. Strength. Reliability. Get Top-Quality Steel Products With Peterson Company—Built to Last Since 1931. – Get A Quote Today!