Fiberglass Grating

Fiberglass Grating & Structural Systems

Peterson Company was founded in 1931 to represent various manufacturers in the electrical industry. Products represented today cover a wide range of Utility, Telecom, and Industrial Equipment, including medium and high voltage, distribution, substation and transmission products. In 1955 Peterson Company’s Steel Division was founded making us one of the oldest grating fabricators/distributors in the United States. Our full-service fabrication facilities have the capabilities to provide specialty metal products for light commercial and heavy industrial requirements. Our inventory has been increased over the years to include not only plank grating, fiberglass grating and structural shapes, but perforated metal, expanded metal, welded and woven wire mesh, roof & floor decking, safety flooring, abrasive stair nosing, and pre-engineered stair systems.

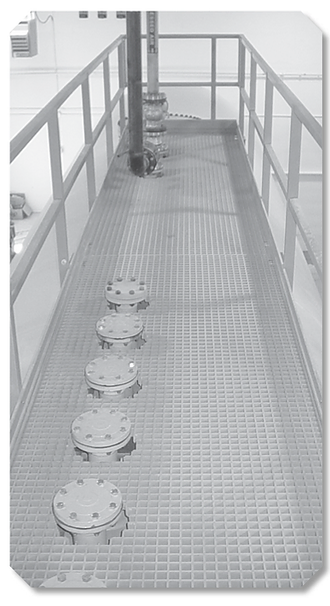

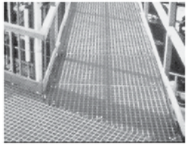

Fiberglass grating is the ideal product when the application calls for a product that is corrosion resistant, fire retardant, light weight and is architecturally appealing.

Fiberglass grating is the ideal product when the application calls for a product that is corrosion resistant, fire retardant, light weight and is architecturally appealing.

Typical applications include floor systems, catwalks, stair treads, work platforms and trench covers.

Weighing considerably less than conventional metal grating, fiberglass grating is easier and less expensive to transport, install and remove.

Fiberglass has been successfully used in many industries including food processing, beverage, water and wastewater treatment, chemical and oil/gas and mining just to name a few.

The two main types of fiberglass grating are distinguished by their method of construction: molding and pultrusion.

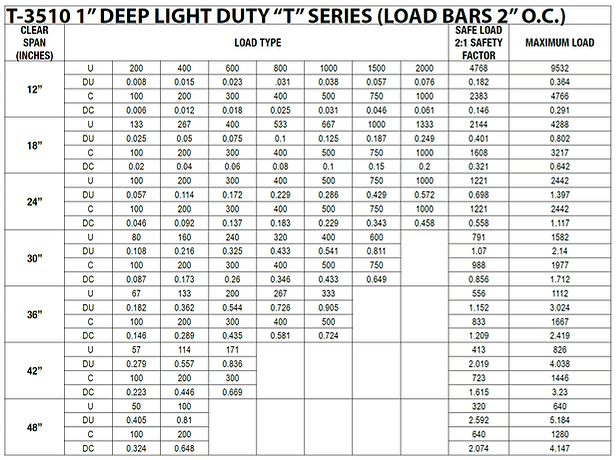

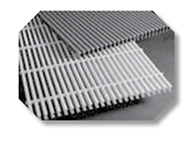

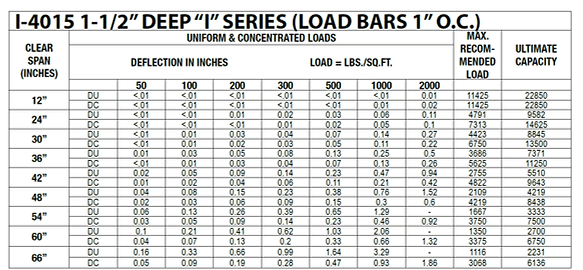

Pultruded is a mostly mechanized process and the type that mostly resembles metal bar grating. It’s the ultimate combination of strength and corrosion resistance and with its standard epoxy grit surface, it offers excellent slip resistance in high traffic areas. It is available with individual bearing bars in either 1″ or 1-1/2″ “I” shapes or a 2″ “T” shape.

Pultruded is a mostly mechanized process and the type that mostly resembles metal bar grating. It’s the ultimate combination of strength and corrosion resistance and with its standard epoxy grit surface, it offers excellent slip resistance in high traffic areas. It is available with individual bearing bars in either 1″ or 1-1/2″ “I” shapes or a 2″ “T” shape.

A protective resin covering the exterior surface of the bearing bars allows pultruded grating to withstand exposure to ultraviolet rays and resist corrosion in harsh chemical environments.

A protective resin covering the exterior surface of the bearing bars allows pultruded grating to withstand exposure to ultraviolet rays and resist corrosion in harsh chemical environments.

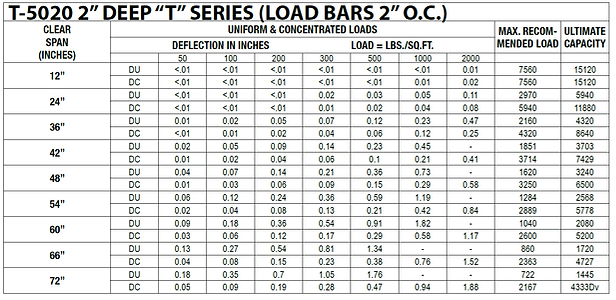

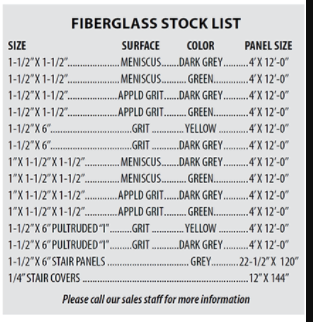

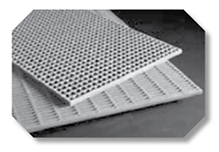

Molded fiberglass grating is a one-piece reinforced polyester or vinylester grating, available in standard panels and sizes. Standard grit surface is available as well as a meniscus (concave) surface. Using the same corrosion resistant resins, molded fiberglass grating works well for floor systems, walkways, work platforms, stairs, ramps, trench covers and catwalks.

Molded fiberglass grating is a one-piece reinforced polyester or vinylester grating, available in standard panels and sizes. Standard grit surface is available as well as a meniscus (concave) surface. Using the same corrosion resistant resins, molded fiberglass grating works well for floor systems, walkways, work platforms, stairs, ramps, trench covers and catwalks.

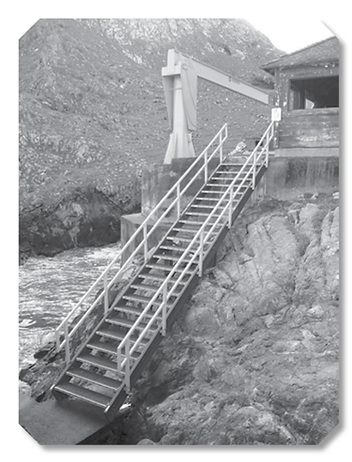

Fiberglass grating is also available for stair treads. Treads are made through the same high-quality process and include a non-slip nosing and optional support angles. Not only can Peterson provide fiberglass stairs, we can be your source for the whole stair system including stringers and handrail.

Fiberglass grating is also available for stair treads. Treads are made through the same high-quality process and include a non-slip nosing and optional support angles. Not only can Peterson provide fiberglass stairs, we can be your source for the whole stair system including stringers and handrail.

In addition to grating, Peterson can offer a wide variety of structural shapes. Standard configurations include angle, beams, square tube, round tube, round tube, flat sheet and solid bar.

In addition to grating, Peterson can offer a wide variety of structural shapes. Standard configurations include angle, beams, square tube, round tube, round tube, flat sheet and solid bar.

Using a combination of fiberglass stair treads and structural members, Peterson Company can provide fiberglass ladder cages. Lightweight and easy to install, this system can provide a safe and slip resistant alternative to standard metal ladder systems.

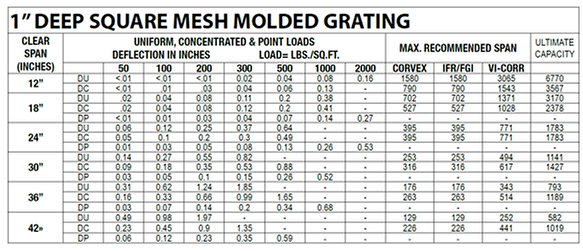

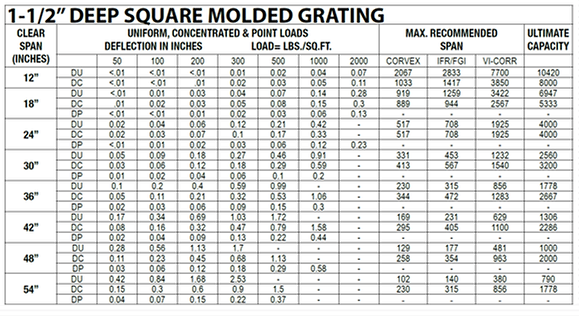

Fiberglass Molded Grating

Molded grating is available in either square or rectangular mesh, providing optimal customer selection. A premium product, molded grating combines fiberglass rovings with thermosetting resin to form a strong, one-piece molded panel. Significantly lighter than metallics, Molded Fiberglass Gratings is easy to install. The square mesh pattern of molded grating allows efficient cutting of the panels so that a variety of flooring layouts can be accommodated with a minimum of waste. Rectangular molded mesh is often used for walkways and trench covers in many industrial applications. Molded Fiberglass Grating is designed to provide the ultimate in reliable performance, even in the most demanding conditions. This advanced grating is proven superior in applications requiring bidirectional strength, corrosion resistance and long, maintenance-free life. Available in either standard meniscus or optional grit-top walking surfaces, molded fiberglass grating offers outstanding skid-resistance for added worker safety.

Molded grating is available in either square or rectangular mesh, providing optimal customer selection. A premium product, molded grating combines fiberglass rovings with thermosetting resin to form a strong, one-piece molded panel. Significantly lighter than metallics, Molded Fiberglass Gratings is easy to install. The square mesh pattern of molded grating allows efficient cutting of the panels so that a variety of flooring layouts can be accommodated with a minimum of waste. Rectangular molded mesh is often used for walkways and trench covers in many industrial applications. Molded Fiberglass Grating is designed to provide the ultimate in reliable performance, even in the most demanding conditions. This advanced grating is proven superior in applications requiring bidirectional strength, corrosion resistance and long, maintenance-free life. Available in either standard meniscus or optional grit-top walking surfaces, molded fiberglass grating offers outstanding skid-resistance for added worker safety.

MOLDED GRATING RESIN SYSTEMS

Peterson offers its fiberglass molded grating line in a choice of five resin systems, assuring a resin system suited to the unique requirements of each customer application.

Vi-CORR® (ORANGE OR GRAY)- A superior resin available only Fibergrate, Vi-Corr® was developed for reliable performance in the toughest environments. This proprietary resin system formulation is the most chemically-resistant available today, offering outstanding resistance to a wide range of highly corrosive environments, ranging from caustic to acidic. In fact, no other resin system can match Vi-Corr®‘s performance in highly acidic environments. Offers as ASTM-E-84, flame spread of 25 or less. Vi-Corr® is also available in a UL Classified resin formulation.

Vi-CORR® (ORANGE OR GRAY)- A superior resin available only Fibergrate, Vi-Corr® was developed for reliable performance in the toughest environments. This proprietary resin system formulation is the most chemically-resistant available today, offering outstanding resistance to a wide range of highly corrosive environments, ranging from caustic to acidic. In fact, no other resin system can match Vi-Corr®‘s performance in highly acidic environments. Offers as ASTM-E-84, flame spread of 25 or less. Vi-Corr® is also available in a UL Classified resin formulation.

IFR (GREEN)- IFR is designed for industrial and chemical processing applications where corrosion resistance is important. This isophthalic polyester resin formulation offers a flame spread rating of 25 or less per ASTM E-84. IFR is also available in a UL Classified resin formulation.

XFR (Gray)- This highly corrosion resistant resin is recommended for use where fire potential is high. This proprietary resin carries a flame spread rating of 10 or less, a level exceeded by no other resin system.

FGI (LIGHT GRAY)- USDA – accepted for food processing applications, this isophthalic polyester resin system meets the unique requirements of the food and beverage industry. FGI carries a flame spread rating of 25 or less.

CORVEX® (YELLOW, GREEN OR GRAY)- An economical polyester grating, Corvex® outperforms a number of competitive fiberglass products and meets the requirements for corrosion resistance found in light industrial and water/wastewater applications. This grating also offers a low flame spread rating of 25 or less.

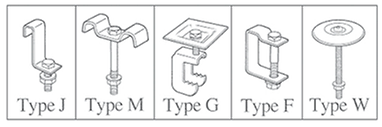

CLIP ASSEMBLIES FOR MOLDED GRATING

Peterson offers specially designed attachments and clips to both fasten panels together and to secure them to support structures. All clips are made of Type 316 Stainless Steel and are available in 1″, 1-1/2″ and 2″ sizes.

TYPE J HOLD DOWN CLIPS- For use in securing grating panels to support frames.

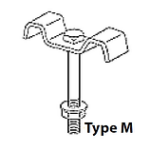

TYPE M HOLD DOWN CLIPS- Used to secure panels to a support using two adjacent grating bars for a secure fit.

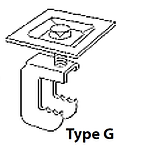

TYPE G HOLD DOWN CLIPS- Designed to attach grating to any structural member flange, 3/4″ or smaller in thickness, with no drilling required.

TYPE F END PANEL CLIP- Provides a simplified method for joining side bars of panels that are butted end to end.

TYPE W- Designed to secure covered grating or FiberPlate to a structure.

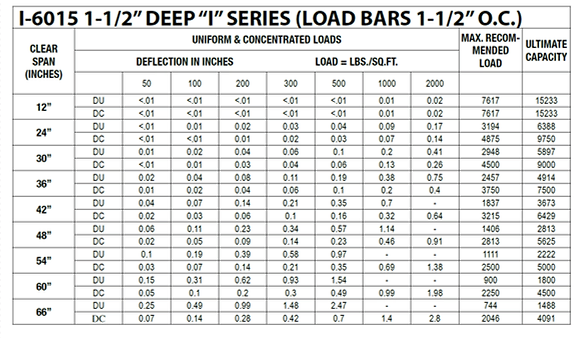

Fiberglass Pultruded Grating

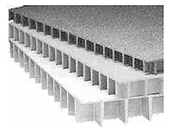

Pultruded grating provides performance far exceeding that of alternative products with a comparable installed cost. This advanced fiberglass grating is designed for use in a wide range of applications that require strength and corrosion resistance. Manufactured with a high percentage of glass within the laminate, pultruded grating combines durability with the highest strength and stiffness available in fiberglass grating. Pultruded grating can be used with confidence in applications where wide support spans are required.

Using a mechanical lock process, pultruded grating is manufactured with a two-piece cross bar configuration which increases the panel’s support and stability under load. The standard grit-top walking surface provides sure footing and a protective synthetic veil, covering the exterior surface of the load bearing bars allows the grating to reliably withstand constant exposure to ultraviolet rays.

Pultruded grating is available in two resin formulations for an accurate match of product characteristics with the application. Both resin systems provide corrosion resistance that is superior to that offered by metal grating.

ISOFR (YELLOW)- This isophthalic polyester resin formulation provides a low flame spread rating of 25 or less and is designed for applications where there is moderate exposure to corrosive elements.

VEFR (GRAY)- With a flame spread of 25 or less, this vinyl eater resin system provides dependable resistance to both acidic and alkaline environments.

Fiberglass Pultruded Grating

PULTRUDED GRATING FASTENERS

Type “M” 316 stainless steel hold down clips used to secure panels to a support using two adjacent grating bars for a secure fit.

Type “M” 316 stainless steel hold down clips used to secure panels to a support using two adjacent grating bars for a secure fit.

Type “G” stainless steel hold clips designed to attach grating to any structural member flange, 3/4″ or smaller in thickness, with no drilling required.

Type “G” stainless steel hold clips designed to attach grating to any structural member flange, 3/4″ or smaller in thickness, with no drilling required.

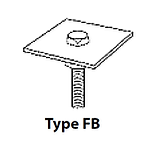

Type “FB” 316 stainless steel flange blocks fit inside close mesh products allowing for installation of cap screws from the top surface of the grating.

Type “FB” 316 stainless steel flange blocks fit inside close mesh products allowing for installation of cap screws from the top surface of the grating.

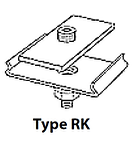

Type “RK” 316 stainless steel fasteners offer effective and more secure means for installing pultruded grating.

Type “RK” 316 stainless steel fasteners offer effective and more secure means for installing pultruded grating.

Fiberglass (Miscellaneous)

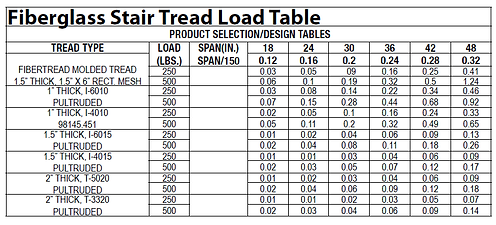

Fiberglass Grating Stair Treads manufactured from quality Fibergrate® molded grating exceed tough OSHA standards for safety, strength, durability and corrosion resistance. Fibertred® is available in the same high performance resin formulation as Fibergate® molded grating and also provides excellent safety characteristics: slip resistance, non-conductivity and a low flame spread.

Unique cutting channels, spaced at 6″ intervals, provide efficient utilization when custom fitting into stairways. These channels also ensure that all standard stair tread’s widths are terminated with closed ends. A 1-1/2″ wide gritted strip is molded into the lead edge of the tread for superior slip resistance. Additional support is required for treads exceeding 42″ width.

Cost efficient, durable Pultruded Stair Treads are slip-resistant and non-conductive. These stair treads offer the same level of safety, strength and corrosion resistance as other pultruded fiberglass products. Designed for use in applications where wider support spans are required, Pultruded Stair Treads are available in 1″, 1-1/2″ and 2″ thickness.

Notes:

Notes:

It is suggested that stair tread deflection be limited to span 150. Deflections based on this ratio are provided at the top of the table. Deflections in the body of the table are for concentrated loads of both 250 lbs. and 500 lbs. A concentrated load is applied at the centerline of the tread, over a width of 4″ and a depth of 6″, starting at the nosing edge to simulate the landing of a foot.

Deflections are not appreciably different due to stair tread depth. Actual depth will vary depending on stair tread configuration.

COVERED GRATING

COVERED GRATING

Covered molded fiberglass grating includes an integral 1/8″ grit surface fiberglass plate molded to the top of any molded grating panel. Covered grating offers a strong, level surface for foot or cart traffic and provides higher stiffness values than that of open mesh grating. Type “W” hold down fasteners are recommended to secure covered grating panels to structural supports in order to eliminate potential warping of the plate. Smooth surface fiberglass plate is optional.

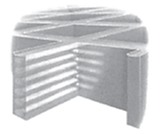

GRATING PEDESTALS

GRATING PEDESTALS

Specially designed legs for 1-1/2″ deep, square mesh molded grating are manufactured to provide sturdy support for elevated flooring. All fixed-height and adjustable legs support flooring for heights up to 60″. Cross bracing is required for flooring elevated more than 24″. Available grating legs include:

(A) FIXED-HEIGHT LEGS W/SINGLE HEAD – For supporting grating up to 60″ above level concrete floor.

(B) FIXED-HEIGHT LEGS W/DOUBLE HEADS – For connecting adjoining panels.

(C) ADJUSTABLE-HEIGHT MINI LEGS – For raising grating 3-1/4″ to 6-1/4″ above uneven concrete floor.

(D) ADJUSTABLE-HEIGHT LEGS W/SINGLE HEAD – For uneven floors designed to be screw-adjusted from atop the elevated floor.

(E) ADJUSTABLE-HEIGHT LEGS W/DOUBLE HEADS – For joining and supporting panels above non-level concrete floor.

SEALING KITS

SEALING KITS

To maintain corrosion resistance and structural integrity, all exposed ends of fiberglass grating or components should be resin sealed after cutting. Peterson offers premium vinyl ester resin sealing kits for its full range of grating products.

FIBERPLATE®

FIBERPLATE®

Fiberplate® sets the standard for high performance structural panel. A rugged fiberglass structural plate with a molded-in, grit top surface, Fiberplate® is designed for use in applications where durability and long, maintenance-free life is critical. As a flooring, FiberPlate is usually installed over structural members, or over existing grating, to provide a solid walkway or to extend the life of a high traffic area. FiberPlate can also be bolted directly to structural beams and used as a wall panel that is resistant to corrosive splash. FiberPlate is manufactured from the same wide range of resins and colors as our molded grating products line. Available plate thickness is 1/8″, 1/4″, 3/8″, 1/2″ and 3/4″. Plate sizes range from 3′ x 10′ to 4′ x 12 ‘. Cut to size pieces are similarly available.

FRP CONCRETE CURB ANGLE

FRP CONCRETE CURB ANGLE

Pultruded fiberglass reinforced plastic (FRP) embedment curb angle provides a secure and durable seat for grating over concrete trenches and pits. Manufactured from corrosion resistant, gray vinyl ester, fire retardant resin, curb angles are pultruded with a built-in continuous anchor that securely locks the angle into the concrete pour.